Managing Tessellated Geometry

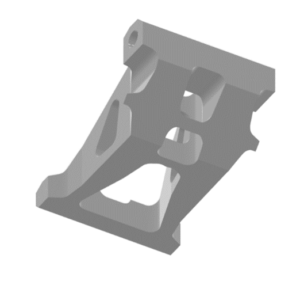

We have all noticed the potential topological optimization has in the past years. From reducing costs to creating innovative ways to use emerging manufacturing methods. It’s a game changer for companies wanting to optimize the performance of their products and reduce their overhead. As beautiful as this technology is, there is a downside worth considering: reconstructing a realistic model to use for manufacturing.

optimization has in the past years. From reducing costs to creating innovative ways to use emerging manufacturing methods. It’s a game changer for companies wanting to optimize the performance of their products and reduce their overhead. As beautiful as this technology is, there is a downside worth considering: reconstructing a realistic model to use for manufacturing.

With the Function Driven Generative Designer (GDE) role on the 3DEXPERIENCE platform, you can quickly

and precisely reconstruct geometry from tessellated results like STL files, cloud points or a result coming directly from 3DEXPERIENCE. This role provides multiple tools to create accurate models according to your manufacturing intentions. You can create models to be 3D printed, casted, or machined and significantly reduce the time between the reception of the optimization results and the physical part being produced.

Turning Complexity into Usability with 3DEXPERIENCE

The GDE licence gives you access to multiple toolsets. The designer can choose to use the free shape design or follow the guided shape reconstruction.

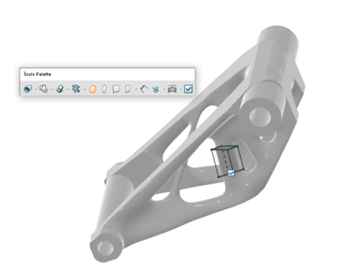

Free Form Tools

Using the free form tools is flexible and precise but can be more time consuming. The reconstruction using free form tools is still very efficient, the user can use the tessellated geometry to construct custom surfaces that follow the general profile of the optimized part as well as removing imperfections that don’t belong in the manufactured product. However, this approach requires the designer to have knowledge about the manufacturing requirements to produce a quality product.

Using the free form tools is flexible and precise but can be more time consuming. The reconstruction using free form tools is still very efficient, the user can use the tessellated geometry to construct custom surfaces that follow the general profile of the optimized part as well as removing imperfections that don’t belong in the manufactured product. However, this approach requires the designer to have knowledge about the manufacturing requirements to produce a quality product.

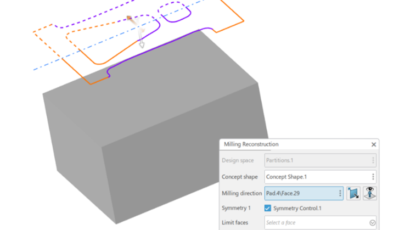

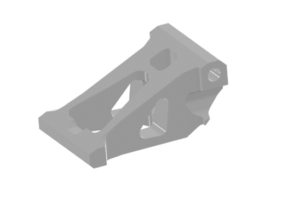

Guided Shape Reconstruction

This requirement for knowledge and insight is greatly reduced by the second method. The guided reconstruction tool gives the user the ability to quickly reconstruct a shape according to milling guidelines to ensure that the product will easily be manufactured. It lets the user define the basic shape of the raw material and the milling directions to ensure the part can be manufactured according to the machine’s capabilities.

This requirement for knowledge and insight is greatly reduced by the second method. The guided reconstruction tool gives the user the ability to quickly reconstruct a shape according to milling guidelines to ensure that the product will easily be manufactured. It lets the user define the basic shape of the raw material and the milling directions to ensure the part can be manufactured according to the machine’s capabilities.

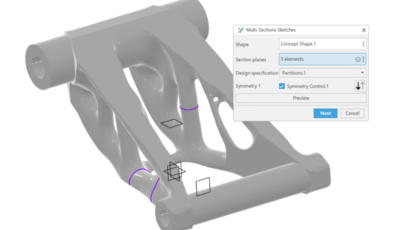

Another interesting tool introduced on this application is the parametric multi-section sketches reconstruction. This option gives you the ability to extract specific area of your optimized model by intersecting planes with the geometry creating an outline. This outline can be used to recreate features using the part design or generative shape design apps. This approach uses the direct input from the tessellated model to create clean and flexible features that the designer can adjust to the correct requirements.

Another interesting tool introduced on this application is the parametric multi-section sketches reconstruction. This option gives you the ability to extract specific area of your optimized model by intersecting planes with the geometry creating an outline. This outline can be used to recreate features using the part design or generative shape design apps. This approach uses the direct input from the tessellated model to create clean and flexible features that the designer can adjust to the correct requirements.

These apps give the user the ability to leverage the full power of topological optimizations while limiting the time and knowledge necessary to send out the product for manufacturing. These skills combined with a good knowledge of the resources available to realize the project can really help a company optimize their

These apps give the user the ability to leverage the full power of topological optimizations while limiting the time and knowledge necessary to send out the product for manufacturing. These skills combined with a good knowledge of the resources available to realize the project can really help a company optimize their

cost to benefit ratio. In an industry where minutes and grams can cost thousands of dollars it can be the difference between making money from the product or not.

What is the 3DEXPERIENCE platform?

The 3DEXPERIENCE platform is the ONLY BUSINESS EXPERIENCE platform that provides software solutions for every department in your organization, from engineering to marketing to sales. It supports the entire value creation process and helps create differentiating consumer experiences. With a single, easy-to-use interface, it powers INDUSTRY SOLUTION EXPERIENCES based on 3D design, analysis, simulation, and intelligence software in a collaborative and interactive environment. It is available on-premises and in public or private cloud environments.

Interested in the platform? Book your free assessment with our team today!