True-Load: The Load Reconstruction Software from Wolfstar Technology

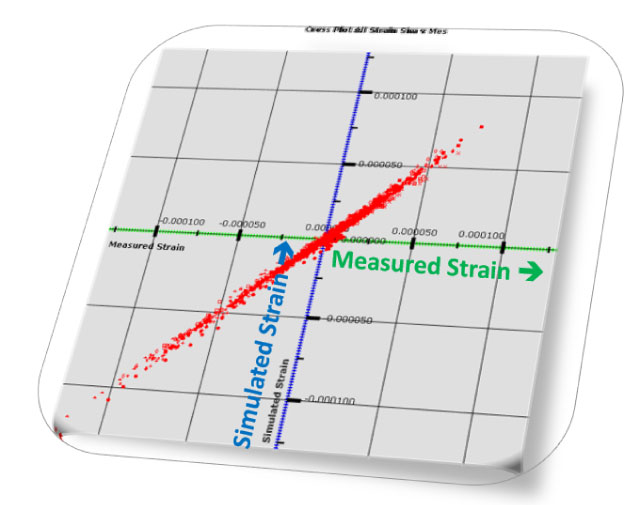

One of the most challenging tasks for an analyst is to develop load cases for their FEA model that match measured strain values. Typically, it will take weeks to develop the right load cases that match just one or two strain gauges at a single point in time. True-Load makes that situation a thing of the past.

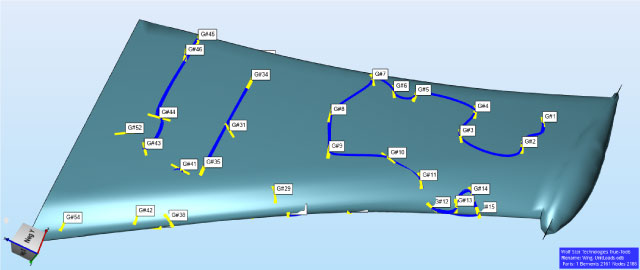

True-Load is a first to market solutions that help engineers understand loads on a structure by correlating test results with FEA models economically. Moreover, the solution leverages FEA models to place strain gauges on unmodified physical parts and then back calculate loading.

Additionally, True-Load directly interfaces to FEA fatigue software to make FEA based fatigue with correlated loading events a natural part of the design cycle.

True-Load

Benefits

- Reduce test and analysis time, correlating strains & loads.

- Reduce test costs (TRANSDUCERS, TIME, DATA) by using a few optimized strain gauges. No modification of test parts.

- Increase the user’s knowledge of the loading on the structure.

- Reduce time and error in setting upscale-and-combine fatigue analysis.

- Provides the foundation for accurate fatigue analysis.

- Get away from the Garbage in – Garbage out issue about loads.

- Produce decision ready FEA analysis using strain correlated loading from the TRUE-LOAD Software.

- Eliminate entire hardware iterations by making proper engineering decisions based on actual loading.

True-Load

Features

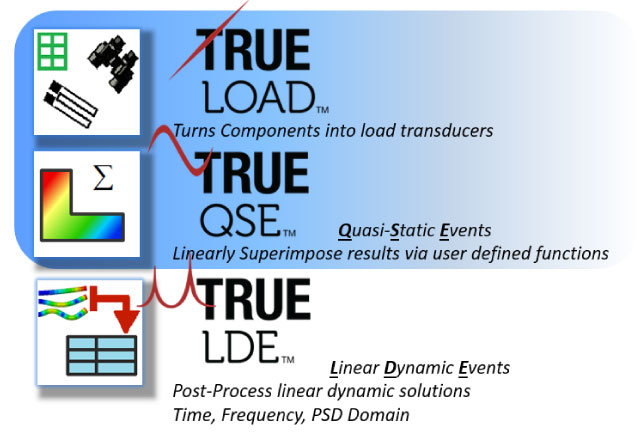

- Integration

- Complexity

- Turn complex components into multi-channel load cells.

- Calculation

- Calculate loading histories from measured strain histories.

- Optimization

- Optimize the location of the strain gauge placement based on FEA unit loads.

- Forecasting

- Provides unprecedented Strain Correlation on all strain channels.

- Quickly iterate on designs using load histories.