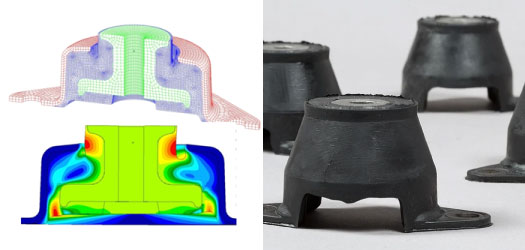

This study was to evaluate the stiffness in all directions of a recreational vehicle engine mount made of rubber, with an inner metal sleeve.

To accurately define the elastomer material model, experimental testing was done at a material laboratory on samples of the rubber. The three required static tests were realized to obtain the material curves for simple tension, pure shear and equal biaxial extension loading. With the test results, a hyperplastic material model was curved fitted on the data using ABAQUS.

With the right material definition, static load cases were analyzed to evaluate the stiffness in several directions.

Force vs. displacement curves were created from the analysis helping the customer to optimize the geometry of the rubber section to fit the vehicle’s requirements in a fast and efficient process