GNA is a recognized world leader in the design and construction of furnaces and equipment for the aluminum industry, especially melting and holding furnaces; homogenizing, annealing and heat treatment furnaces; cathode sealing equipment and associated machinery.

Their advanced design, control systems, and construction techniques provide long service life and class-leading efficiency and reliability. Operator safety and comfort are primary goals in the design of their equipment: user-friendly features are built into all GNA furnaces, extending from the access ladders/stairways and service platforms to the control systems.

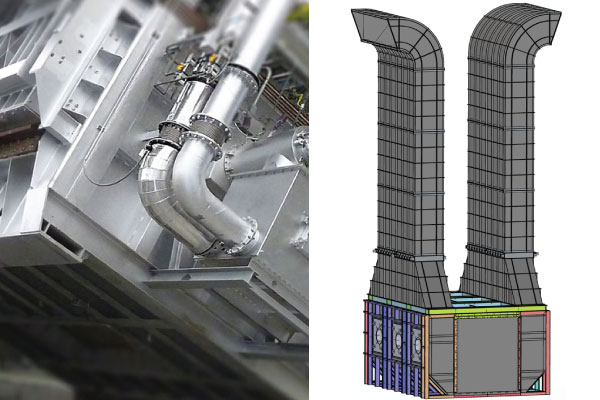

To keep improving their advanced design, GNA reached out to Optimec to better understand the behavior of the air flow in a chamber to cool down aluminum billets that were just forged.

To help them, Optimec used Computational Fluid Dynamics simulations (CFD) applying several volume flows at fan locations and measured the pressure drop inside the cooling chamber and inside both inlet and outlet chimneys. It allowed the team to draw the pressure drop versus velocity curve of air, giving the client precious information guiding the choice of the adequate fans.

Once the fans were chosen by GNA, Optimec conducted transient analyses to predict the aluminum billets cooling time to room temperature as well as the temperature homogeneity across the 100+ billets.

SOLUTIONS

- Adapting the client 3D Computer Aided Design (CAD) geometry for Computational Fluid Dynamics (CFD) analyses

- Steady-state CFD analyses inside the full assembly (inlet chimney, cooling chamber, outlet chimney)

- Transient analysis to estimate the billets cooling time

- Recommendation on chamber redesign to optimize the cooling efficiency

As a result, the client was able to choose adequate fans, maximizing efficiency and insuring the right sizing of the fans. They also have a better understanding of the flow pattern inside the cooling chamber, thanks to virtualization.

Optimec’s analyses also allowed them to predict the cooling time with the fan model they picked and compare the value with other products for efficiency ranking.