Key results:

1. Numerical verification of the compliance to the norm

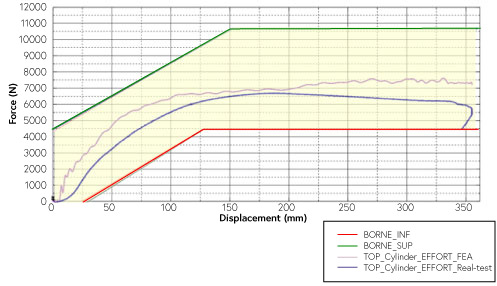

2. Force curve is almost identical to the physical test

3. Time and cost reduction

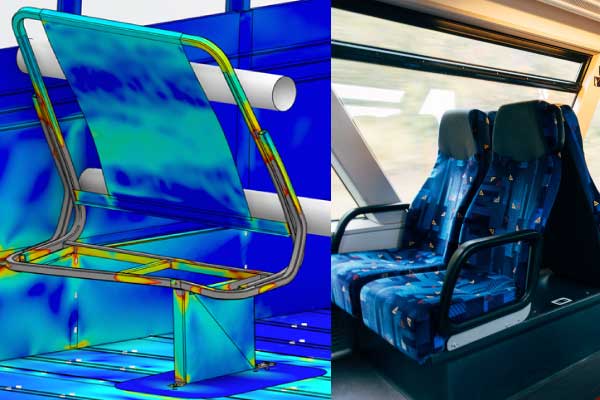

The objective of the FMVSS222 standard is to enhance the safety of school bus occupants by reducing the number of deaths and the severity of injuries resulting from impacts with structures within the vehicle during crashes and sudden driving maneuvers. Finite Element Analysis (FEA) using Abaqus software allows to ensure compliance with the norms without conducting high-priced physical tests.

Specifically, the focus was on the passenger seat of the school bus, which has another seat in front of it. It was subjected to the application of force through loading bars. The test involved applying a horizontal force in the forward direction through the upper bar until 452W joules of energy were absorbed in deflecting the seat back.

The test comprised two cylindrical bars rotating around their z-axis at the pivot attachment point and was performed in three steps:

- First, a force of 3,114W was applied horizontally in the forward direction through the bottom loading bar at the pivot attachment point.

- Second, the force was reduced to 4671N (1,557W) while maintaining the pivot point position of the bottom loading bar in position, the top loading bar was positioned to be laterally centered behind the seat back.

- Third, a horizontally imposed displacement of 356mm was applied in the forward direction through the upper bar. The goal was to check if 1356J of energy was absorbed while deflecting the seat back.

The bench seat had already passed the FMVSS222 standard when tested independently. However, the client required confirmation that the seat still met the standards once installed inside the bus.

Challenges related to this project

1. Highly non-linear behavior of the structure

2. Numerical modeling of the test guidelines

3. Modeling of bolts preload in explicit computation

The seat bench, along with its bolts and connections, were modeled in the bus environment using finite elements. Then, to address the non-linearity issue, explicit computation was employed by shortening the span of the test to imitate the quasi-static phenomenon.

Two calculations were performed on the entire model to mimic the real conditions of the physical test, following a particular displacement curve. To resolve the bolts preload issue, numerous iterations were run to determine the right values.

Meticulous attention to detail permitted a realistic simulation, as illustrated in the figure, which demonstrates the close alignment of the force curves in the physical and numerical tests.

Based on the results of the simulation, our client was able to conduct their tests confidently, knowing that the bus is an adequate environment for the seat bench to pass the test.