Plastic containers for food or for industrial applications must support a minimum top load charge for stacking but must also be as light (thin) as possible to reduce material.

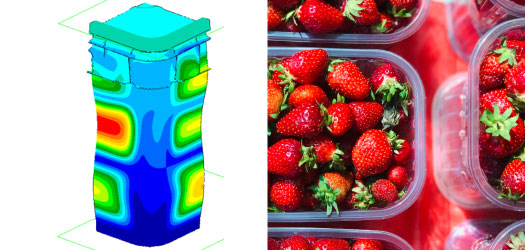

A structural Finite Element Analysis was performed on several design iterations of a container to obtain the best trade off between top load resistance and weight.

Non-linear material definition was used for the polymer and non-linear solver (MSC MARC) were used to accurately predict the buckling point and post bucking behavior.

Key Benefits

- Rapidity of the results

- Minimizing weight without physical prototypes

- Optimal material thickness to meet top-load specification