ISIGHT Software : ROBOT FOR SIMULATION PROCESESSES & DESIGN OPTIMIZATION

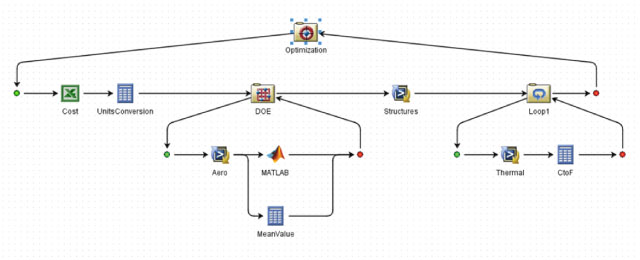

Isight software and the Simulia execution engine are used to combine multiple transversal models and applications in a flow of simulation processes, automate its execution through distributed processing resources, explore the resulting design space and identify the optimal design parameters subject to restrictions requests.

Market pressures are more present than ever before to reduce time to market for new products, while guaranteeing high quality and reliability. At the same time, products are becoming more and more complex, combining mechanics with electronics and other physics. This reality forces manufacturing companies to analyze thoroughly new products during the design phase.

In order to achieve this, companies use many in-house and 3rd party applications to analyze product performance & cost. The compatibility between these applications is difficult to maintain, and, in most cases, only be run by a few individuals.

The engineering simulation process put in place with these different applications is slow and complex and generates a lot of unstructured data and results. It only allows us to look at single aspects of the problem at a time.

Isight software allows creating an automated workflow of simulation processes, managing the transfer of data from one application to another in order to simulate the complete problem, across different physics. It also allows to launch design of experiment and optimization scenario to easily study variability in design parameters and optimize products performance (Multi Discipline Optimization, MDO).

Isight software

Benefits

UNDERSTAND YOUR DESIGN

Products are becoming more and more complex. Using Isight software to drive your simulation process allows interrogating more widely the simulation models by varying design parameters and thus generate hundreds of predictions automatically. By studying more design alternatives, the product will be more performant and more reliable.

Without a tool like Isight software, it is nearly impossible to manually take into account all possible variability in geometries, material properties, loads, etc. to fully understand the design space and the possible behavior.

REDUCE DESIGN TIME

Isight software is working like a robot for simulation, automatically launching applications and transferring inputs and outputs from software to another in a prescribed simulation workflow. It significantly speeds up the simulation work. Often used an automated workflow can be saves as the template for reuse or training.

Isight software also allows to doing parametric optimization of 3D geometries to quickly get an optimized part. It can automatically change a geometry by interacting with CAD software to optimize shapes with FEA in a loop process.

IMPROVE QUALITY

Predicting behavior of products in a Multiphysics environment is difficult. By using Isight software capabilities to do Multi Discipline Optimization (MDO), it is possible to obtain the required performance of products without compromise. Quality of products will be improved.

Isight software

Feature

- Use Isight software like a robot by creating automated simulation workflows.

- Includes a standard library of software components like Excel, MATLAB, ABAQUS, ANSYS, CATIA and many others to use in a workflow.

- Several DoE algorithms available to explore the design space.

- Sensitivity analysis of design parameters.

- Comprehensive selection of parallelized optimization techniques.

- Able to realize single of multi-objective optimization

- Powerful real-time tools to interpolate results of computationally intensive realistic simulations.

- “Surf” the design space graphically and interactively.

- Easy creation of graphs and tables, 2D and 3D plots to visualize results.

- Visualize parameters relationships on performance.